CAD Product Design Services

A real passion for Donkey Work Design is helping young and small businesses develop through our CAD product design services. We offer a range of what we call idea to reality services, supplementing our CAD Design and Drafting Services.

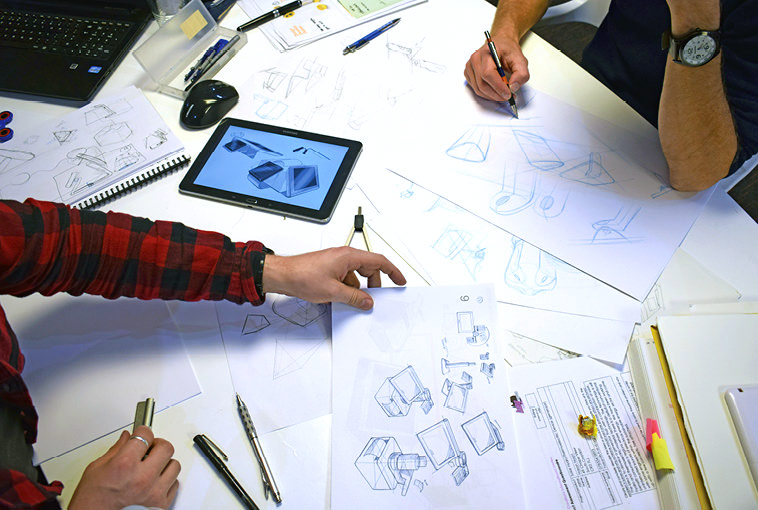

Design Consultation

Either taking an existing idea and making it reality, or an existing design and taking it to the next level. Taking the basis of an idea and using manufacturing experience to advise on how best to proceed with the design. Analysis of existing designs, amplifying their strengths and eliminating their weaknesses.

Photorealistic Rendering

Simply put, photorealistic rendering shows a 3D design in a way that makes it look like a photo of a real product. For example, this is really useful to market a product which isn’t manufactured.

An important step in bringing a concept to market in the leanest possible manner is a photorealistic render. An alternate step to going straight from solid modelling to manufacture is the rendering to market the product without first making a fully manufactured product. Not to be used instead of prototyping but as well as, after the concept has been sufficiently proven.

Animation

Using an animation of the product or process as a means of marketing the product in a lean manner. Supplementing the rendering above.

Rapid Prototyping

3D Printing as a service – bringing ideas into tangible reality. Sometimes seeing something in your hands shows you something that you miss in your head, on your page or on your screen – a prototype is an important step in the product development process. Teaching clients how to fail fast, fail often, but must importantly to fail cheaply – product development is all about trial and error, bringing an idea to market in the leanest possible manner. Making a scale model or simplified part is an important intermediate step.

Key product or process prototyping? Taking a part of the product or process and manufacturing a key element to allow for further testing that ensures a proof of concept.

3D Printing Services offered at Donkey Work Design

At Donkey Work Design we offer FDM printing, using a variety of materials in a selection of colours, with a build volume of 220mm (W) x 220mm (D) x 250mm (H).

Reverse Engineering

Using 3D Scanning to take an existing product and get it into 3D space quickly has come on leaps and bounds in the last decade, and is a service that we offer here at Donkey Work Design.

3D Scanning as a service – Taking an existing product and working backwards is always a great way to get your product to market in the most lean way possible, minimising your capital focus on research and development.

3D Scanning services offered at Donkey Work Design

At Donkey Work Design we offer 3D scanning using the structured light method of scanning via a handheld device for measuring the three-dimensional shape of an object using projected infrared light patterns and a camera system to measure their relevant distance and construct the overall shape of the object.

Simulation

Simulation in product design is a powerful tool that enhances the development process by allowing us to virtually test and analyse products before physical prototyping. By integrating simulation, we can evaluate how a product will perform under various conditions, such as stress, airflow, and motion, without the need for costly and time-consuming physical tests. This capability enables the identification and correction of potential issues early in the design process, optimising performance, improving safety, and reducing development costs. Simulation also supports iterative design, allowing for rapid experimentation and refinement of ideas, leading to more innovative and reliable products.

Mechanical Product Design and Development

Our service is focused on designing products based on their physical, material and ergonomic attributes. Mechanical product design and development isn’t just nuts and bolts either. Our CAD services can help you design:

- Plastic Parts

- Sheet Metal Components

- Fabricated Structures

- Machined Parts

- Tool Design

- Linear Motion Systems

- Rotary Motion Systems

- Gearing & Driveline

- And much much more!

We see product design and development from a mechanical engineering perspective. The majority of how your product will be interacted with is in its physical form, how it looks, how it feels, how it’s assembled and how it’s manufactured.

We impose an emphasis on the mechanical design and functionality of the product throughout both the new product development (NPD) and product improvement (PI) processes. We have experienced mechanical engineers ready to take you by the hand through design for manufacture in your NPD and PI processes.

Mechanical Product Design and Development is at the heart of what we do. Firstly, we are mechanical engineers and see the product design and and development from this perspective.

We split our role in product design and development into 2 key areas:

- 3D Visualisation

- Design for Manufacture

3D visualisation not only tackles the initial conceptual product design, but also the pre- and post-manufacture modelling and imagery for marketing the product. Whereas design for manufacture is the core process of developing the product design. This includes rationalising it into the various parts and processes from which it will be manufactured.

See here for more in depth look into our full range of CAD Product Design Services which support this.

Digital Product Design and Development

CAD is at the core of our business. For instance, we use our CAD tools in 3 main ways:

- Design for Prototype and Manufacture

- Design for Extended Reality (XR).

- Design for Photorealistic Rendering

Firstly, we design all our products in 3D space, to scale with their real life counterparts. This helps to more easily get across a digital product’s design. We do this using solid modelling software. Simply put, this means that the models we create have thickness and are represented as solids. This is perfect for manufacture.

Secondly, we can use the 3D models that we create for interactive purposes. By using extended reality, our designs are laid over virtual or real scenes so that their scale can be observed. Lastly, we use special rendering software to make the product look close to what it would in real life.

Additionally, we use specialist hardware to aid in digital product design. For example, our 3D scanner is what we mainly use to bring real products into digital 3D space.

Product Design for Extended Reality (XR)

Using XR, i.e. Augmented Reality (AR) and/or Virtual Reality (VR), as a means of marketing the product in a lean manner.

Augmented Reality is about the senses – enhancing the physical world by overlaying visual stimuli. Virtual Reality requires a headset and allows full immersion in virtual spaces. Similarly, Mixed Reality is the blend of physical and virtual worlds, allowing digital content to interact with real life.

You don’t have to put on a headset, your smartphone, tablet or PC can transport you to a digital product in a 3D space. AR product design is something which we see becoming more popular and have the tools to make it possible for you too. It’s a great way to take something digital and make it tangible.